Acidic Electrolyzed Oxidizing Water Ionizer For Hospital

Acidic Electrolyzed Oxidizing Water, another name “Hypochlorous acid” is a neutral, low-molecular-weight small molecule with no charge, allowing it to easily penetrate the negatively charged cell membranes and efficiently disrupt functional enzymes inside bacteria. Its bactericidal effectiveness is approximately 100 times greater than that of alcohol or iodine-based disinfectants. It can rapidly eliminate a wide range of microbial pathogens within a short period. Even highly resilient spore-forming bacteria can be killed within 10 minutes, achieving a destruction rate of over 99% against bacteria, fungi, and viruses.

Model:

PAE-10HOCl Output:

≥1L/minHOCl concentration:

40~200ppmPH range:

5.0~6.5ORP range:

800~1000mvCell type:

Membrane CellRate power:

220V AC 50HZAdditive:

SaltControl mode:

Auto ControlAcidic Electrolyzed Oxidizing Water Ionizer For Hospital

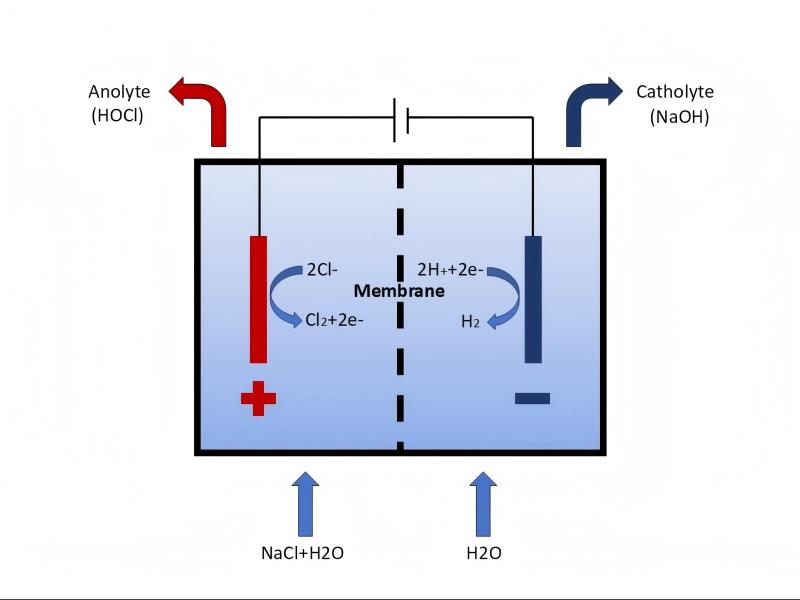

Principle of electrolysis

By adding low-concentration sodium chloride to softened water and conducting an electrochemical reaction through electrolysis in a diaphragm electrolyzer, an acidic aqueous solution with hypochlorous acid as the primary bactericidal component is generated.

Using only salt and water as raw materials, the anode chamber produce strongly acidic electrolyzed water, while the cathode chamber produce strongly alkaline electrolyzed water. When weakly acidic electrolyzed water is required, the strongly acidic and strongly alkaline solutions are mixed to adjust the pH to the appropriate level. Any excess strongly alkaline electrolyzed water is discharged.

Application For Hospital

Sterilization of Surgical Instruments and Items Cleaned Manually Prior to Sterilization

After manual cleaning according to WS 3102, flush and soak for disinfection with flowing electrolyzed oxidizing water for 2 minutes. Rinse with purified water for 30 seconds, then remove and air-dry or wipe dry with a sterile cloth before proceeding with sterilization as required.

Disinfection of Endoscopes

After pre-processing, leak testing, cleaning, and rinsing of the endoscope according to WS 507 requirements, completely submerge it in electrolyzed oxidizing water. Connect the outlet of the electrolyzed oxidizing water to all channels of the endoscope using a full-channel irrigator, and use a power pump to fill all channels with the disinfectant. Flush and soak for disinfection for 3 to 5 minutes, then perform terminal rinsing and drying according to WS 507 requirements.

Disinfection of General Medical Devices

After thorough cleaning of general medical devices, flush and soak them in flowing electrolyzed oxidizing water for 3 to 5 minutes.

Hygienic Disinfection

When using electrolyzed oxidizing water for disinfection, first rinse with alkaline electrolyzed water for 20 seconds, then flush and disinfect with flowing electrolyzed oxidizing water for 1 minute, followed by a final rinse with alkaline electrolyzed water or tap water for 10 seconds. When using slightly acidic electrolyzed water for disinfection, flush and disinfect for 1 minute, then rinse with tap water for 10 seconds. If hands are heavily soiled, they should be thoroughly cleaned before proceeding with the disinfection process as described.

Skin and Mucous Membrane Disinfection

Rinse or repeatedly scrub the area with electrolyzed oxidizing water or slightly acidic electrolyzed water for 3 to 5 minutes for disinfection.

Disinfection of Dental Unit Waterlines (Note: Not covered in our instruction manual)

For initial disinfection, use 40 mg/L slightly acidic electrolyzed water to flush and disinfect the tubing until the water quality at all outlets meets the GB 5749 standard requirement of ≤100 CFU/mL for total bacterial count. For daily maintenance, use 10 mg/L slightly acidic electrolyzed water for routine sanitation of the tubing and for mouth rinsing.

--------------占位---------------

Specifications

| Model | PAE-10 | |

| Dimension of Host Machine | 650*600*1770mm | |

| PH of Slightly acidic water | 5.0-6.5 | |

| Free Chlorine Concentration | 40~200 mg/L | |

| Output | ≥1L/min | |

| Power | 220V AC 50hz | |

| Inlet water requirement | Tap Water (included softener) | |

| Storage Tank | External storage tank | |

| Control Mode | PLC control | |

| Remote Control | mobile/computer remote control | |

| Installation Environmental | ventilation good | |